Panel Beating Services in Auckland

Experienced Panel Beaters You Can Trust

At Mt Roskill Collision Centre, we specialise in all types of panel damage repair. With over 30 years of experience, our certified panel beaters provide expert service, reliable advice, and peace of mind so you know your vehicle is in the best hands.

Bumper Repair & Replacement

From minor dents to serious damage, our skilled technicians offer fast, affordable bumper repairs with precision and care.

Learn moreCollision Repair

Accredited with most major insurance providers, making the repair process straightforward and stress-free. Let our team handle your claim and your repair.

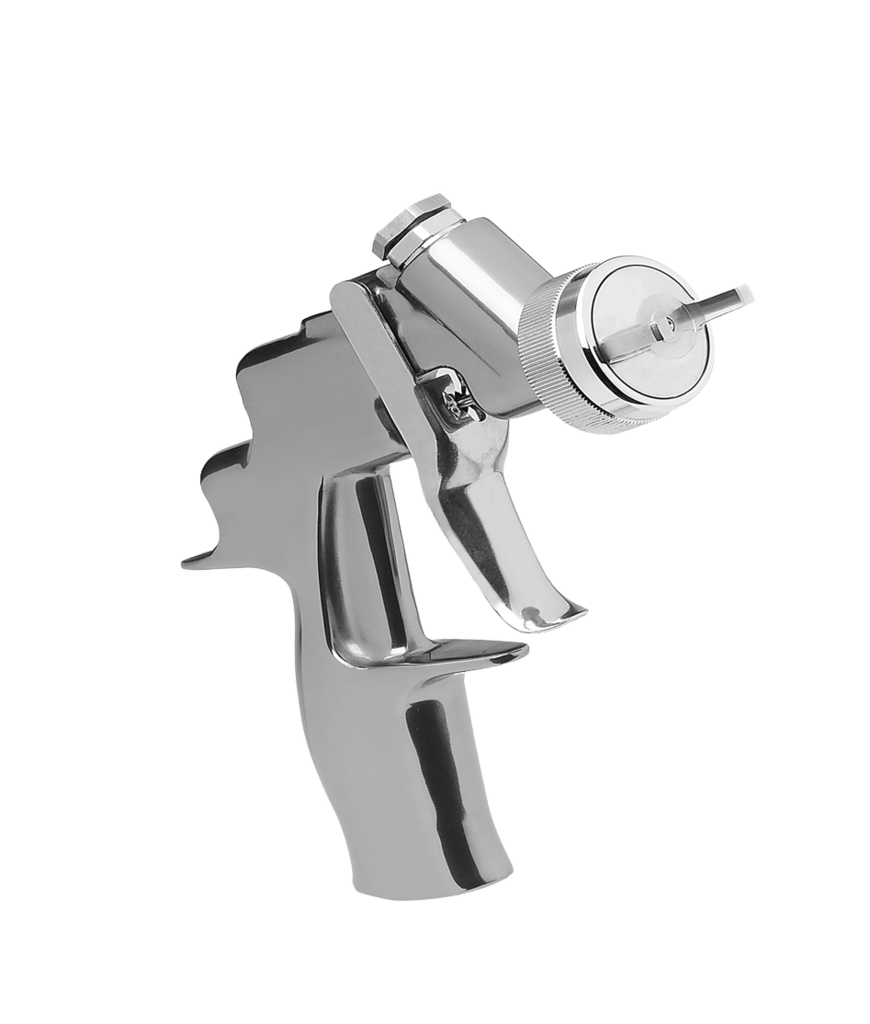

Learn moreCar Paints

Our experienced car painters take pride in every job large or small. We’ll match your paint perfectly and restore your vehicle’s finish to factory standard.

Learn moreCar Polishing

Bring out the shine with our expert car polishing service. Great for hiding fine scratches and refreshing your vehicle’s overall look.

Learn moreCar Touch Up

Just need a small fix? Our ‘nip & tuck’ touch-up service will restore your car to its former glory without the cost of a full respray.

Learn moreHeadlight Restoration

Cloudy headlights can affect safety and style. We’ll restore their clarity to keep your car looking sharp and your visibility clear.

Learn moreCurbed Wheel Repair

Restore your rims to like-new condition. We remove scratches, scuffs, and curb damage with precision and care.

Learn moreDent Removal

We offer expert paintless dent removal across all types of vehicles no matter how small or significant the damage.

Learn moreOur Panel Beating Process

Book a time for assessment

We inform your insurer of the cost

You drop in for repair

We repair it like new

You drive it away

Panel Beating Services

We provide thorough inspections of the vehicle’s external panels and substructures using visual expert analysis as well as use electronic measurement systems to check factory tolerances.

We assess impact severity, metal fatigue, stress fractures and this allows us to distinguish between reparable panels and those requiring replacement as per manufacturers recommendations..

You receive a clear, itemised quotation including labour hours, material costs, and estimated time-to-completion. We also consult your insurer where applicable, to ensure repair scope aligns with policy limits and compliance standards.

We employ a combination of traditional metalworking and modern techniques such as cold shrinking, panel induction heating, and PDR (paintless dent repair) where suitable. Larger deformations are addressed using body hammers, dollies, and pull systems like spot weld pullers or glue-based tab systems for non-intrusive correction.

For rust-affected areas, we cut out oxidised metal sections to prevent further spread, and fabricate matching patch panels. All repairs are sealed with zinc-rich epoxy primers and cavity wax to inhibit future corrosion. The aim is to restore both the surface contour and tensile strength of the affected panel in accordance with manufactures recommendations.

If a panel’s structural integrity is compromised, such as excessive stretching, tearing, or rust perforation, we proceed with complete panel replacement. This involves spot or MIG welding (depending on OEM guidelines), precise seam alignment, and post-weld planishing to maintain dimensional tolerances.

On modern vehicles, we follow manufacturer-recommended procedures for bonding or riveting (e.g., for aluminium or composite panels) and restore crumple zones and intrusion beams where applicable. All welding is followed by metal treatment, weld-through priming, and corrosion protection application.

We use a mix of mechanical and manual straightening techniques, including hydraulic pulling benches for chassis realignment when required. Surface panels are reprofiled using fine panel beating tools, such as slappers, body files, and shrinking discs to achieve uniformity in curvature and panel tension.

Unlike filler-dependent repairs, our approach aims to minimise body filler depth by restoring the original panel geometry through precision hammer forming and panel tuning. Where minor filling is necessary, we use high-performance, low-shrink polyester fillers followed by progressive sanding stages to achieve a glass-smooth surface.

Surface preparation is critical to achieving an invisible repair. After metalworking is complete, we apply an etch primer followed by a high-build primer-surfacer to fill minor imperfections. We then block sand using dry and wet techniques across various grits to eliminate texture and ensure optical smoothness under light reflection. All adjacent panels are feathered and blend-masked to ensure a seamless transition.

Before the vehicle is sent to our paint division,adjacent panels are scanned with a colour spectrometer, matched to perfection then sprayed on test panels to test accuracy before panels are wiped down with anti-static degreasers and pre-treatment solutions to eliminate contaminants that could compromise adhesion or finish.

Every stage of the repair is logged in our workshop management system, including photo documentation, measurement records, material batch numbers, and technician sign-off at each milestone. This ensures traceability, quality control, and seamless communication with insurers.

All vehicle repairs, private or insurance are recorded and stored individually for warranty purposes with before-during-and-after photos for transparency. This level of documentation also supports warranty servicing and resale confidence for your vehicle.

Trusted by Leading Car Insurance Providers In New Zealand

Book Now. Pay Later.

Always Interest Free.

With Afterpay and Zip Pay, you can spread out your payments over time interest free.

*Zip pay is only available for panel beating services.

Super Gold Card Members

We value our seniors! Click below to view exclusive offers for SuperGold Card holders.

Explore Offers